As a company with sustainable and ethical values at the heart of our culture, providing responsible garment afterlife solutions is of utmost importance to ensure our company is operating as circularly as possible and we are not creating more waste than traditional retail.

Garments will circulate through the Refresh system as much as possible, being mended and laundered. They will be worn so much that they will inevitably return to us at some point in a condition that is no longer acceptable to be rented. In this case we will send them to our partners at The Formary Wellington.

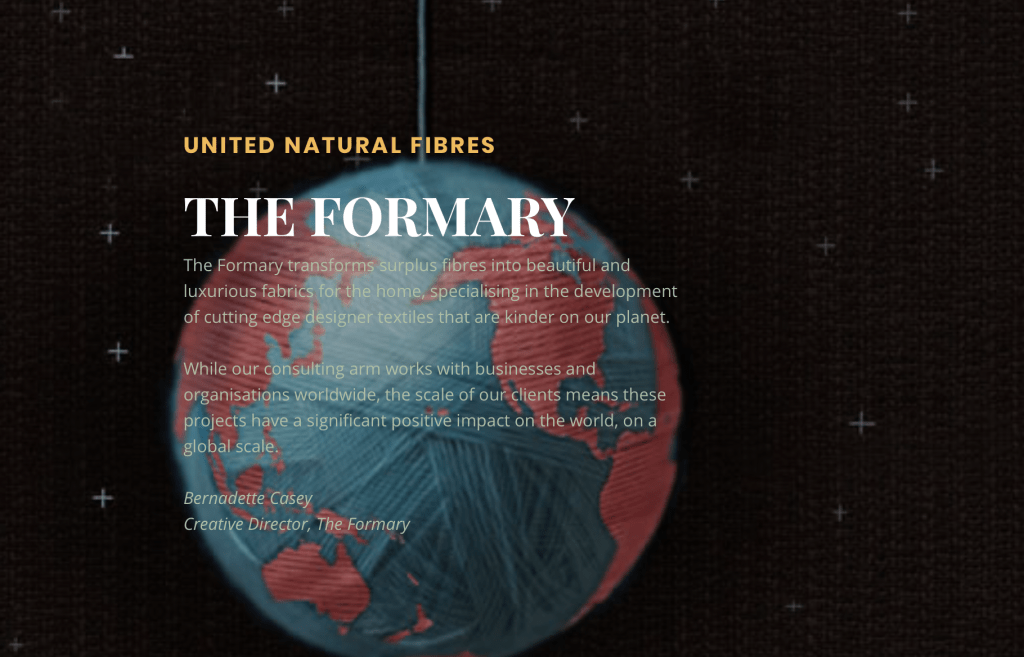

The Formary

The Formary, located right here in Wellington, is a global leader in fibre redesign. They form mutually benefitical partner with businesses and organisations worldwide to transforming fibre waste into valuable, marketable products.

Refresh would work collaboratively with the organisation to identify the viability of the waste fibre of our natural fibre garments and perform the initial fibre research for framing research and development projects.

The formary would then manage the technical and scientific development of new products from our waste fibre. Once the product is developed, the supply chain can be put into motion – from waste fibre collection through to processing and to market through their global distribution networks.

Examples of their previous partnership projects:

NZ POST

Produce around 860,000 uniforms annually.

“Not satisfied with dumping in landfill or sending their used uniforms to third world countries, New Zealand Post decided to lead the way in addressing how corporations deal with used uniforms.

New Zealand Post turned to The Formary to develop a long term, scaleable, business model for the reuse of end of life garments.

Textile waste is a growing issue across the globe, with millions upon millions of tonnes being wasted every year. It’s estimated there is 105 million kilos a year of re-useable fibre that is currently being dumped in New Zealand landfills alone at an astronomical cost of about $17 million.

The Formary converts these into fibre for new textiles and products using a centuries’ old process for producing linen and hemp, with fibres put through a traditional retting process that breaks down the plant to release the fibre.”

Source:

Home